| CLICK HERE FOR INDEX PAGE |

| TYPES OF CHISELS |

| V. Ryan © 2003 - 2024 |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

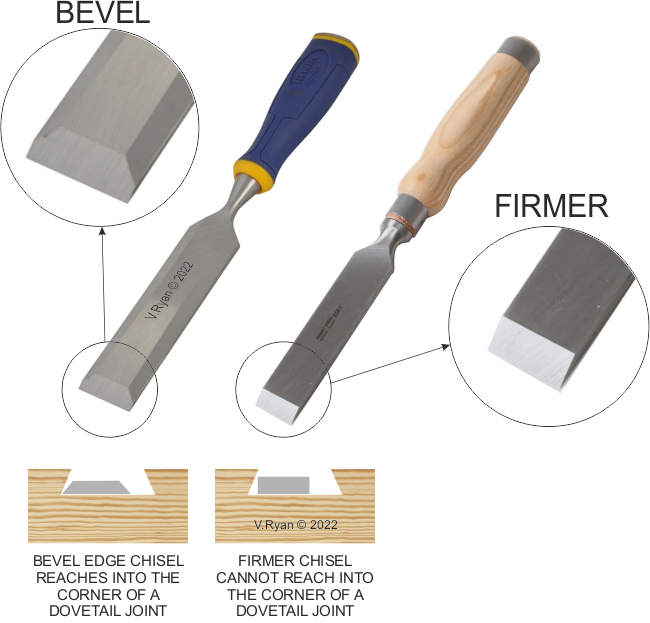

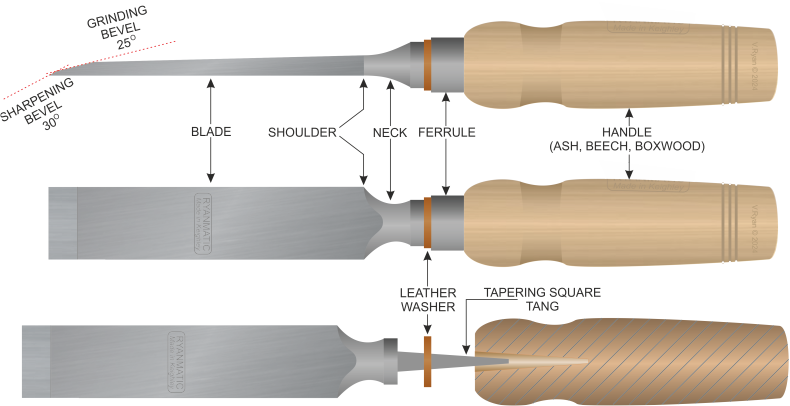

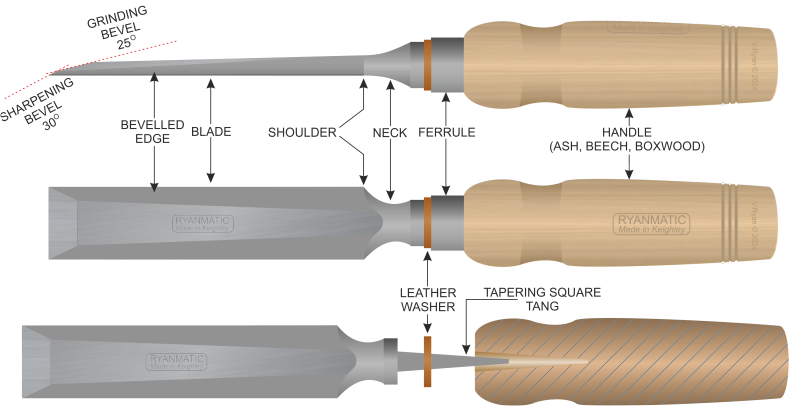

| There are many different types of chisels and each has a particular use. Some of the more common chisels are shown below. The handles of most chisels are made from ash, beech, box wood or plastic and a mallet (not a hammer) is normally used to apply force. |

| Safety is always a consideration when using chisels.

The diagram below shows a paring chisel being used to shave the

edge of a piece of wood a small amount. Each time the mallet forces the

chisel downwards a small amount of wood is parred away from the edge.

Whatever chisel is selected to be used they all should be sharp. A blunt

chisel tends to slip off the surface of the material being cut. If the

chisel slips in the direction of the person using it a serious accident

can occur. Another rule relating to the use of chisels is that the material being cut should be held firmly in a vice of cramped to a bench top. Furthermore, keep both your hands behind the cutting edge, do not be tempted to place one hand in front of the chisel. One slip with the chisel will cause an accident. |

|

| The two animations below, show how easy it is to have an accident with a chisel. Think - safety first. |

| This example shows that the material has not been clamped and a blunt chisel is being used. The material will slip, potentially causing an accident. |

|

| Hands should not be near the sharp edge of a chisel and should be behind the direction of movement of the chisel. The animation shows how hands and fingers can be in danger, when using a chisel. Never place hands or fingers in front of a chisel. Never hold the wood / material in place with your hand - always clamp the material down. |

|