V.Ryan © 2024

| CLICK HERE FOR INDEX PAGE |

| THE BLOCK PLANE |

V.Ryan © 2024 |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET |

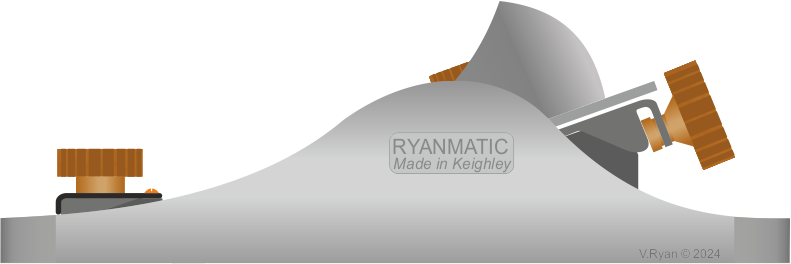

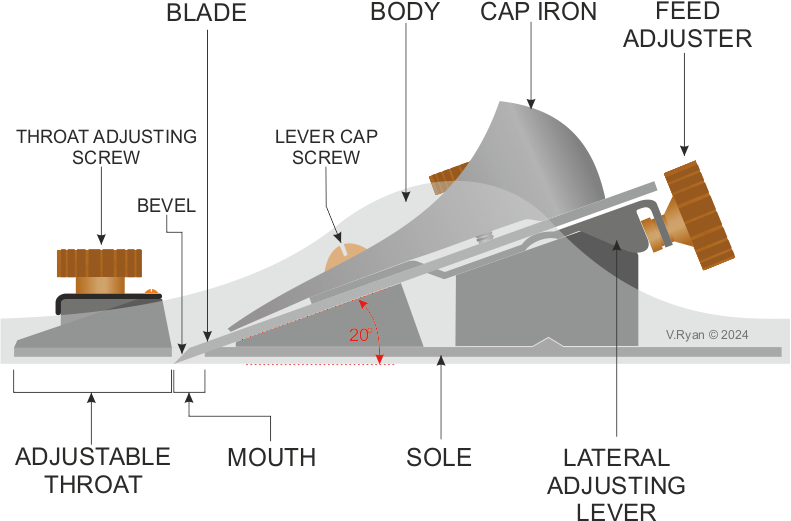

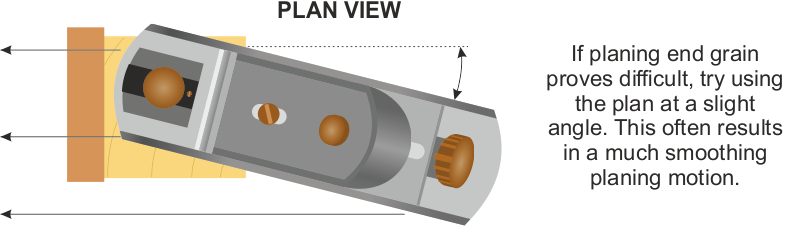

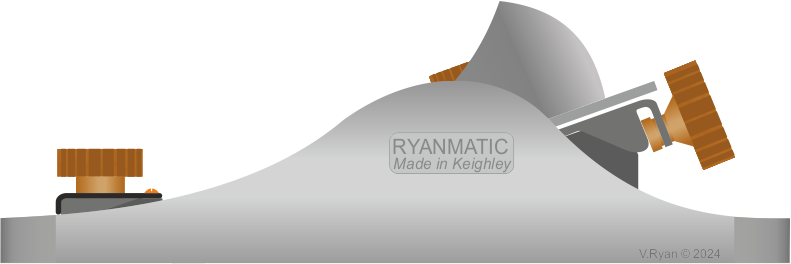

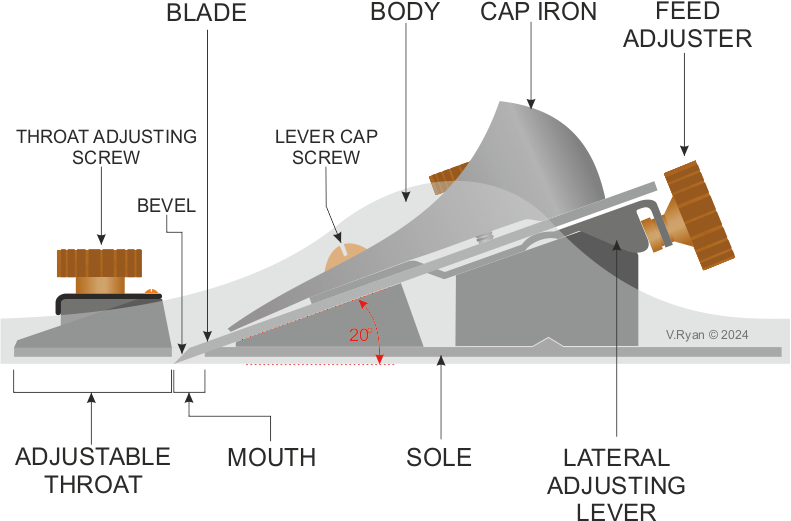

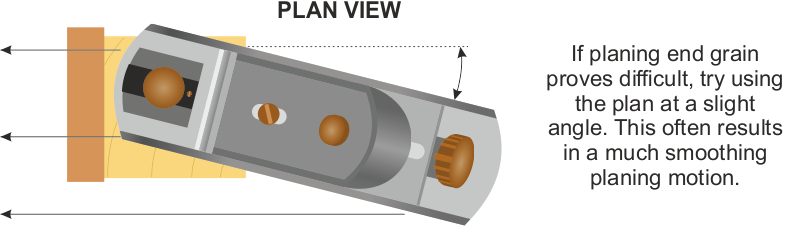

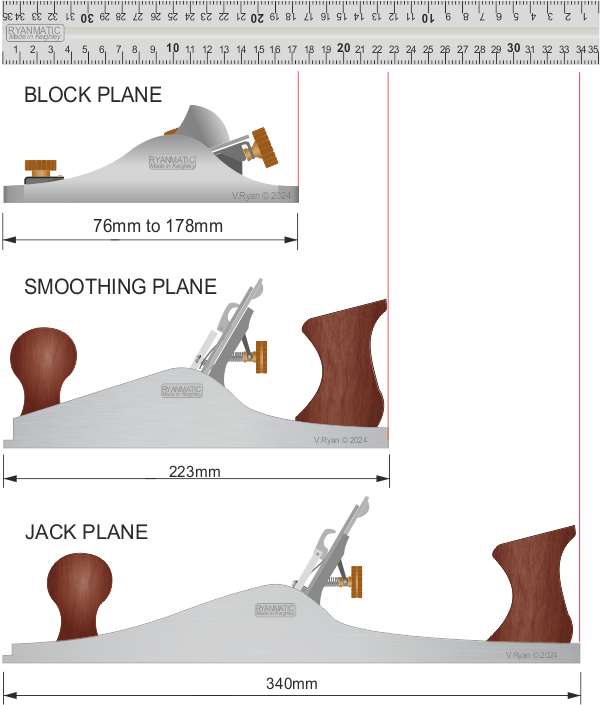

| A block plane is small compared to other planes. It is used to ‘plane’ end grain and is useful when producing chamfers and smoothing surfaces. The block plane is held in one hand, with the second hand sometimes applying pressure to the front. The blade angle of a typical block plane is 20 degrees, with the bevel angle being 22-25 degrees. |

|

|

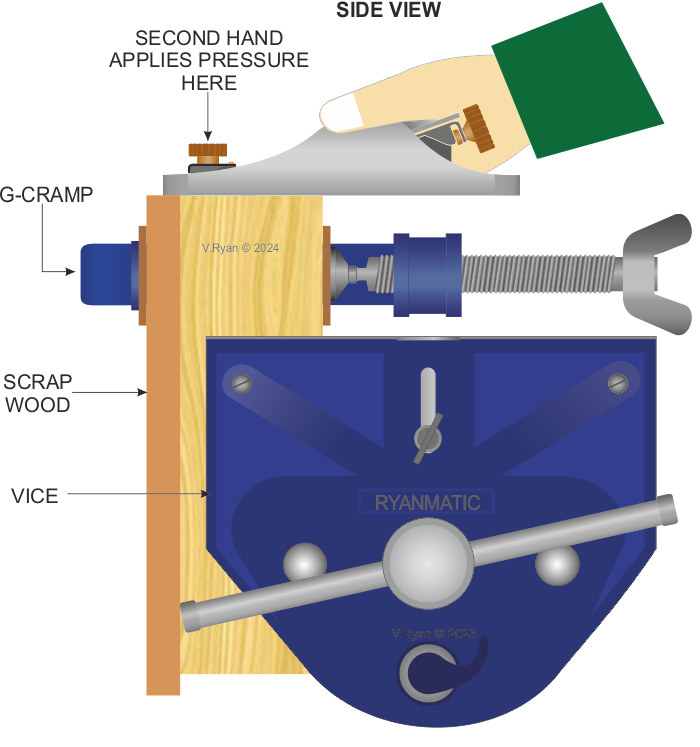

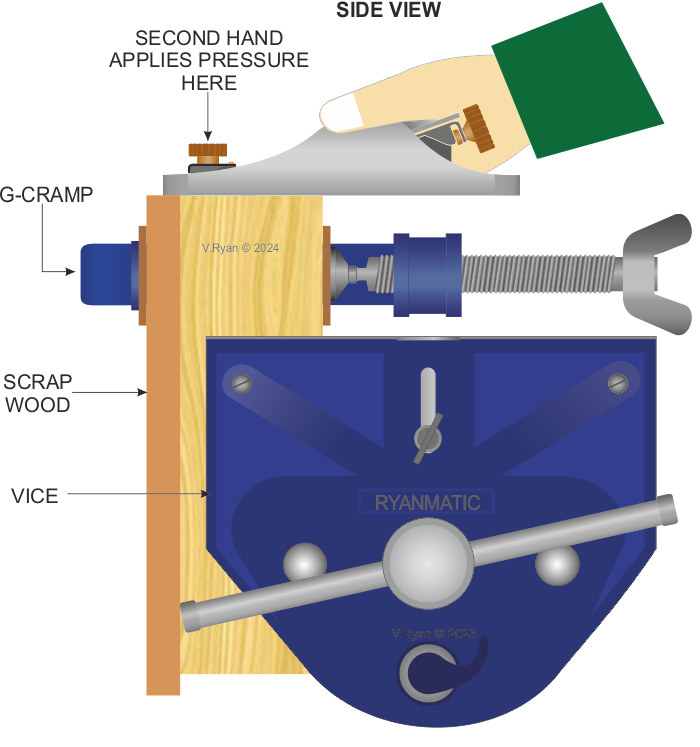

| BLOCK PLANE BEING USE TO PLANE END GRAIN |

| When planing end grain, the workpiece is held high in the vice. This leaves room for a g-cramp to be used to clamp scrap wood to the far side. The clamped scrap wood prevents the wood from splitting, when being planed. |

|

|

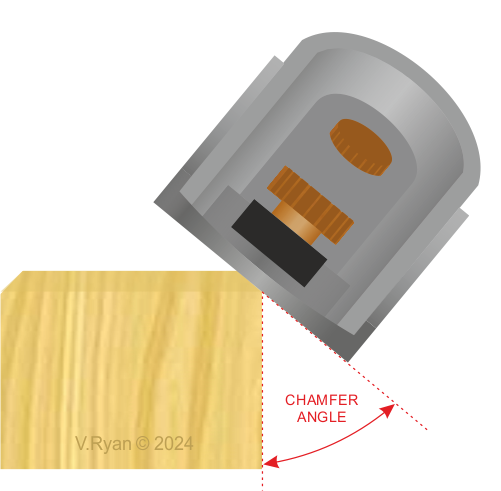

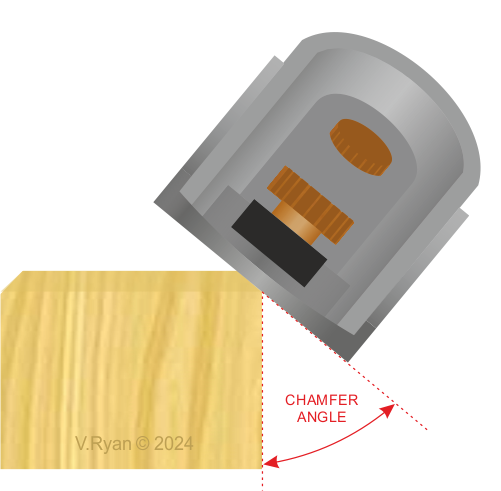

| PLANING A CHAMFER WITH THE BLOCK PLANE |

| When using a block plane to create to a chamfer, it is held at the angle of the chamfer and pushed along the edge. Fine shavings are cut repeatedly, until the chamfer is complete. |

|

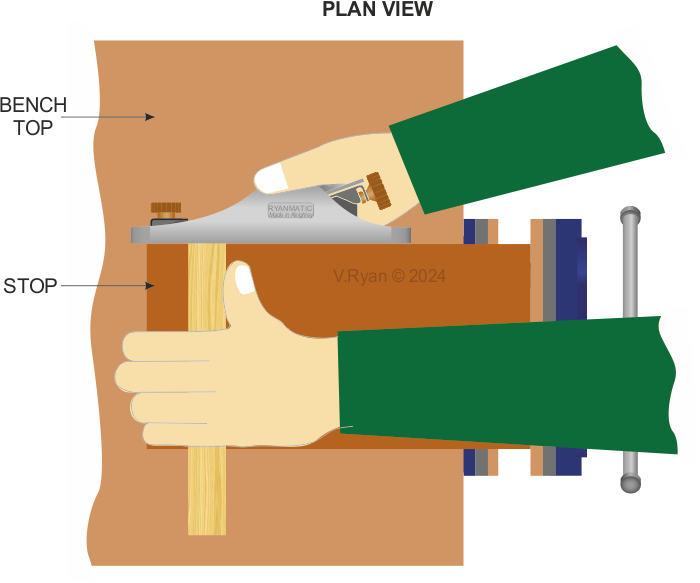

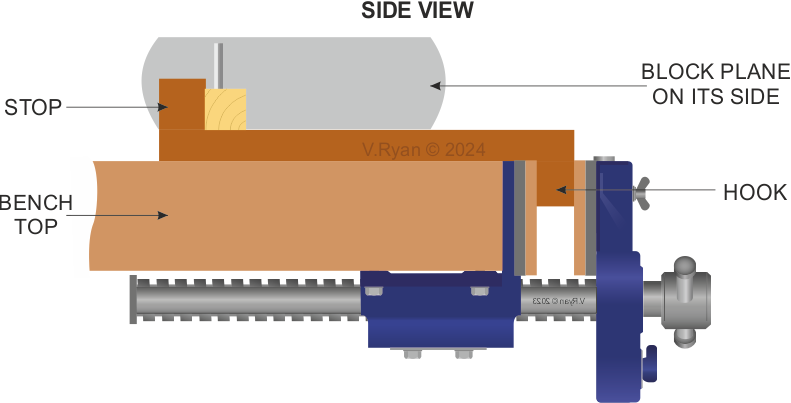

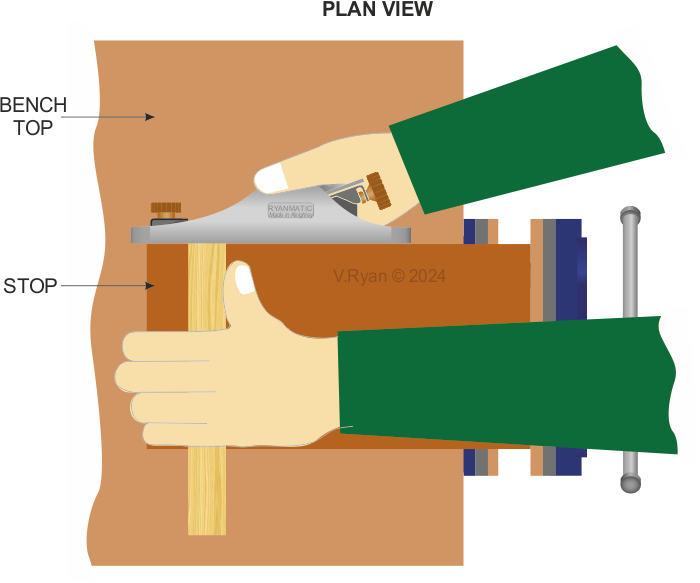

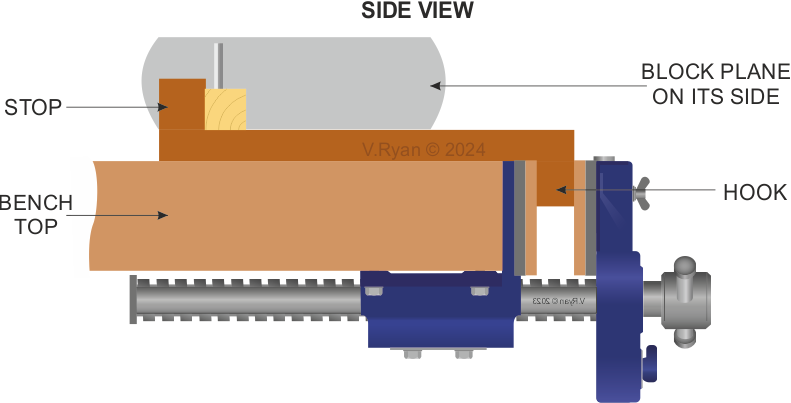

| PLANING END GRAIN USING A BENCH HOOK AND BLOCK PLANE |

| A block plane can be used in conjunction with a bench hook. The bench hook is secured in the woodworking vice and the workpiece is pushed firmly against the ‘stop’. The block plane is placed on its side and pushed with the other hand, removing fine shavings. The ‘stop’ of the bench hook ends to minimise the risk of splitting the end grain. |

|

|

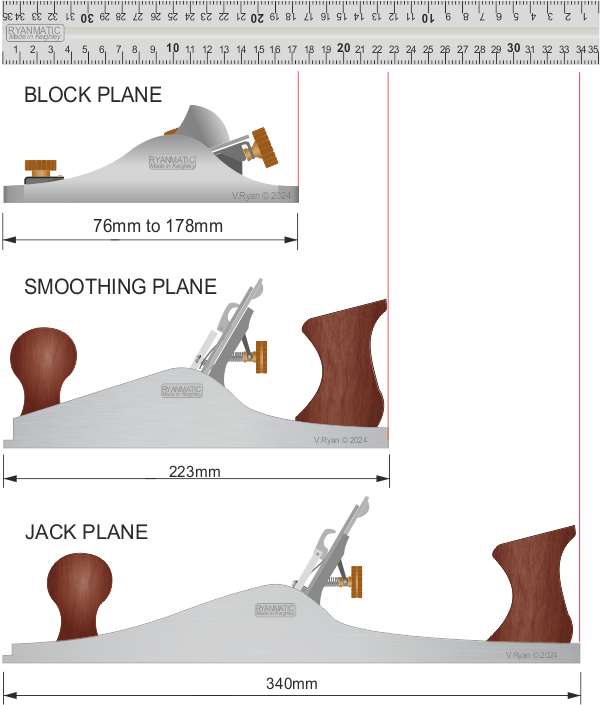

| RELATIVE SIZE OF THREE COMMON PLANES |

|

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

|