| CLICK HERE FOR INDEX PAGE |

| |

| STILLSON WRENCH / PIPE WRENCH |

V.Ryan © 2024 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET |

| |

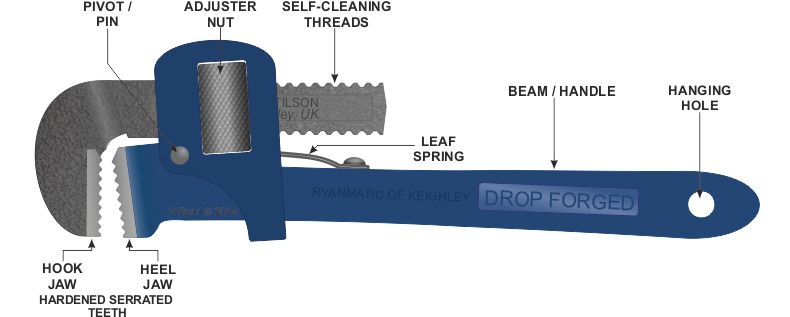

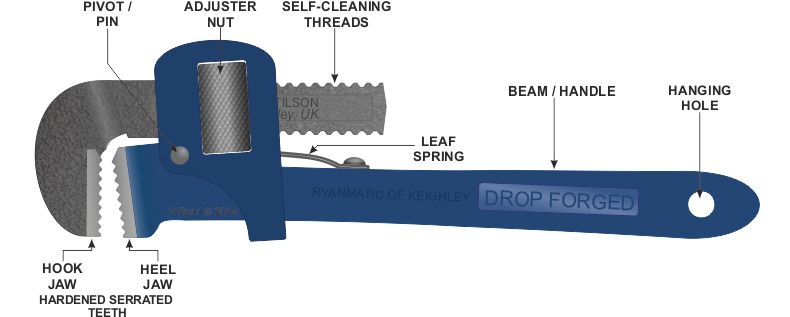

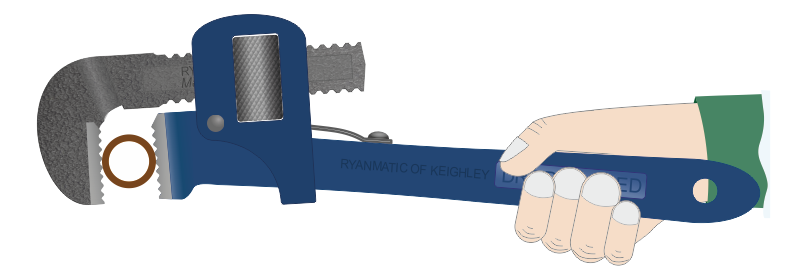

The Stillson wrench / pipe wrench, is used to grip and turn pipe / tube and cylindrical forms. The wrench is named after the original designer, Daniel Stillson (patented 1869). The serrated teeth are ideal for gripping the smooth surface of pipe. The slight movement / play in the jaws, help them grip effectively.

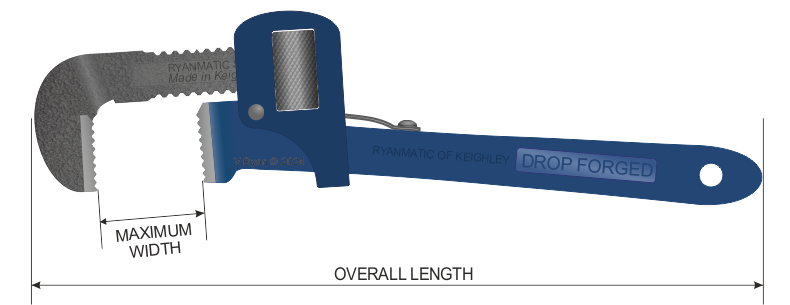

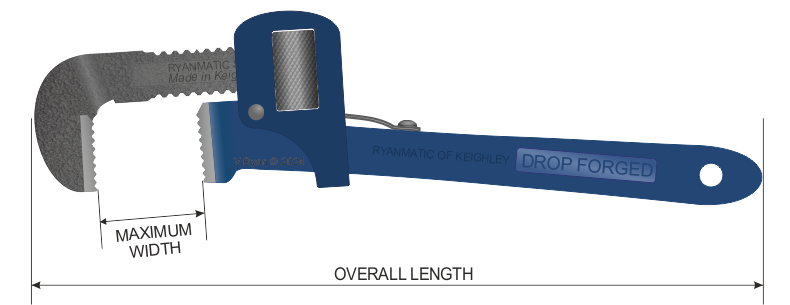

Stillson wrenches are supplied in a range of sizes (determined by the maximum width of the material being gripped and overall length from jaws to the end of the handle), normally 150mm to 1200mm.

A typical Stillson wrench is manufactured from forged carbon steel, with the jaws / teeth machined and hardened through heat treatment. |

| |

|

| |

|

|

| |

|

| |

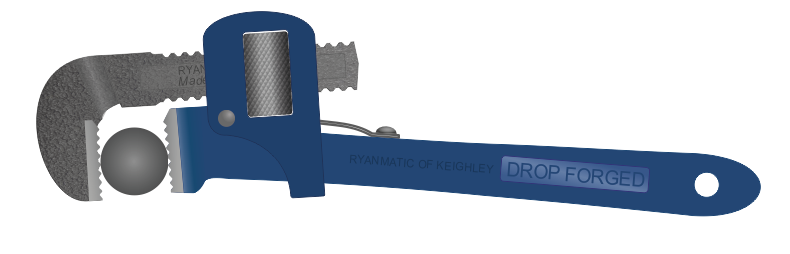

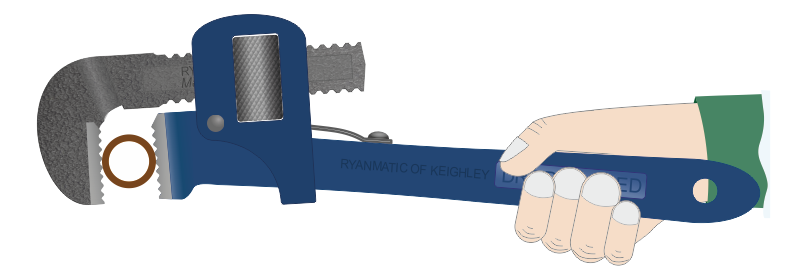

The main use of a Stillson wrench is for gripping and turning threaded pipes and other fittings, when they are been assembled / disassembled. However, care is required to prevent the teeth leaving marks on the surface.

Plumbers use Stillsons for general work on water and heating pipes. Mechanics consider them useful when working on exhaust systems. Construction workers find them extremely helpful when assembling and disassembling scaffolding. They are also useful for taking apart rusty components that are corroded together.

A Stillson wrench is not recommended for tightening or loosening hexagonal bolts. This can result in damage, because of the harsh nature of the teeth, in combination with the force multiplied by the handle, acting as a lever. |

| |

|

| |

|

| |

|

|

| |

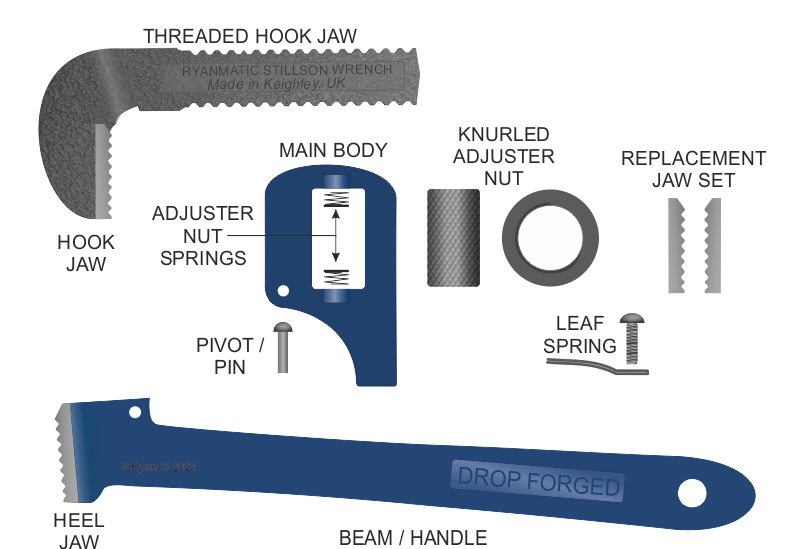

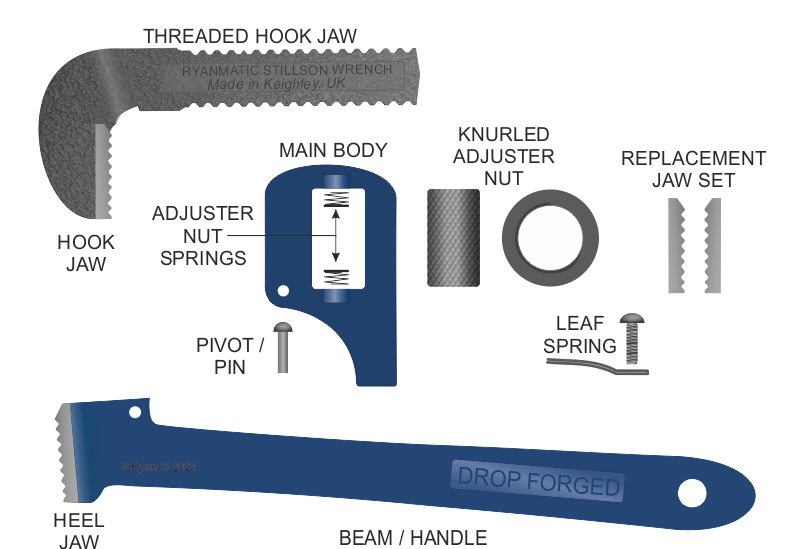

| DISASSEMBLED STILLSON WRENCH |

| |

| A disassembled Stillson wrench is shown below. Models vary according to the manufacturer. It is worth noting the adjuster springs. These sit within the main body and help to keep the ‘adjuster nut’ rotating smoothly. |

| |

|

| |

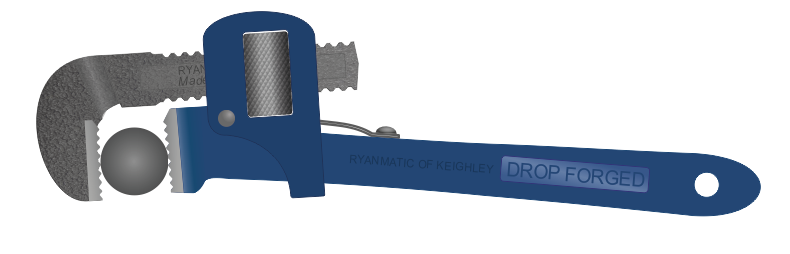

| ALTERNATIVE DESIGN - PIPE WRENCH |

| |

|

| |

|

|

| |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

| |

|

| |

|