V.Ryan © 2024

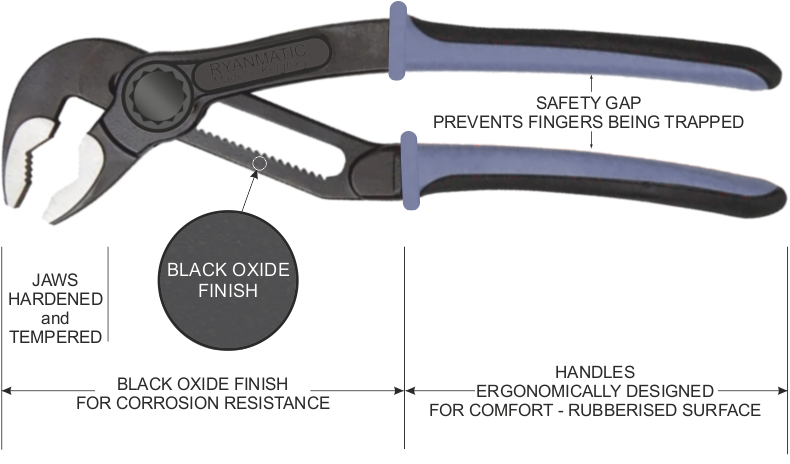

Water pump pliers are manufactured from alloy steel, usually hardened carbon steel, for strength and wear resistance. Most pliers have an anti-rust, black oxide finish to the surface, which is produced through a chemical process, providing excellent corrosion resistance. The finish is visually appealing and resists everyday wear and tear.

The jaws are heat treated to ensure that they are hard wearing. This is a process whereby the jaws are heated to a specific temperature and quench rapidly, changing the structure of the metal. A second heat treatment process called ‘tempering’ takes place. This produces the correct balance between hardness and toughness, reducing the likelihood of the metal becoming brittle and breaking when in use.

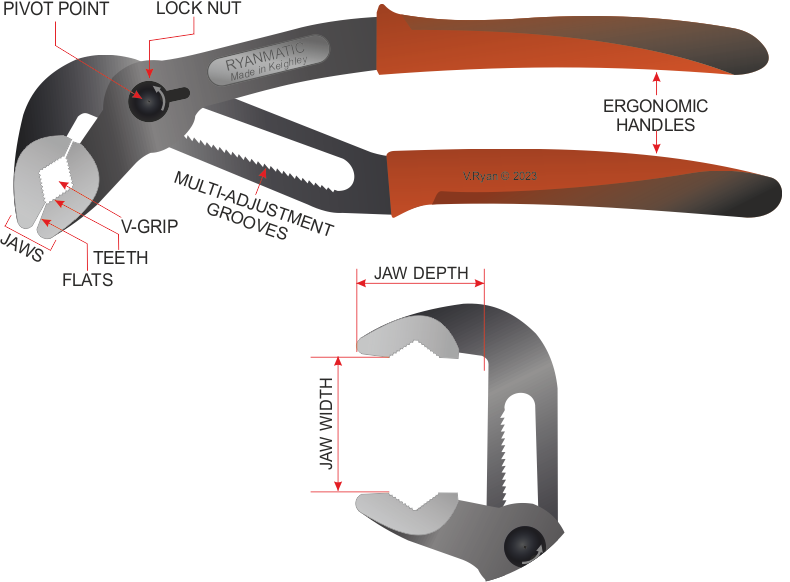

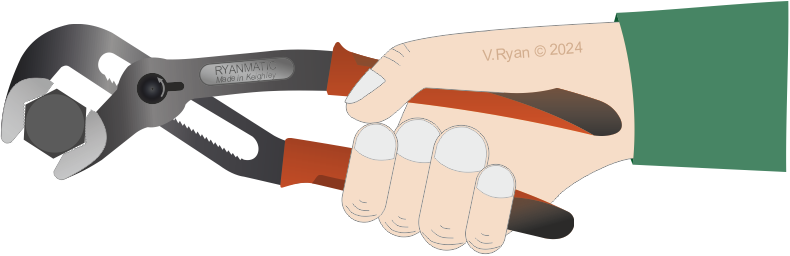

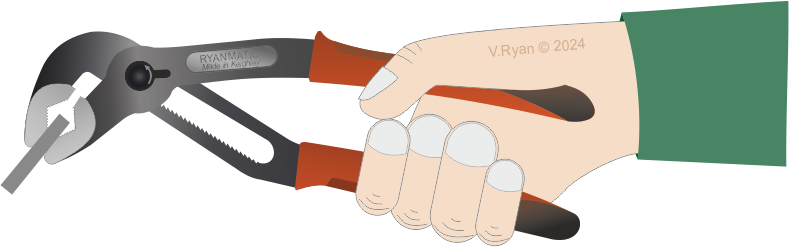

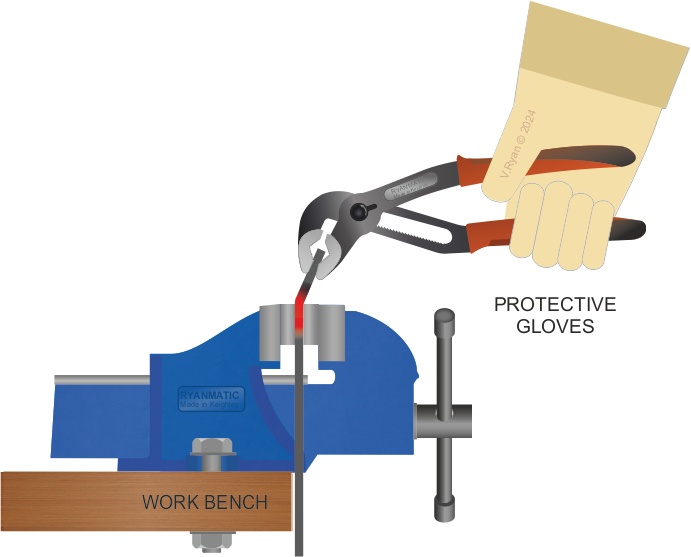

The handles are designed to prevent the trapping of fingers, as the handles are brought together. They are ergonomically designed, to fit the hand, for comfort.