V.Ryan © 2024

| CLICK HERE FOR INDEX PAGE |

| SCREWDRIVERS |

V.Ryan © 2024 |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET |

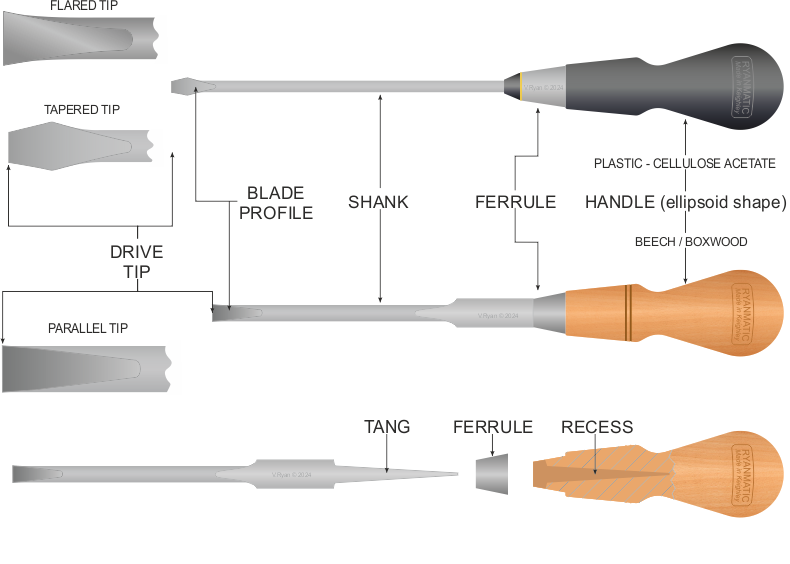

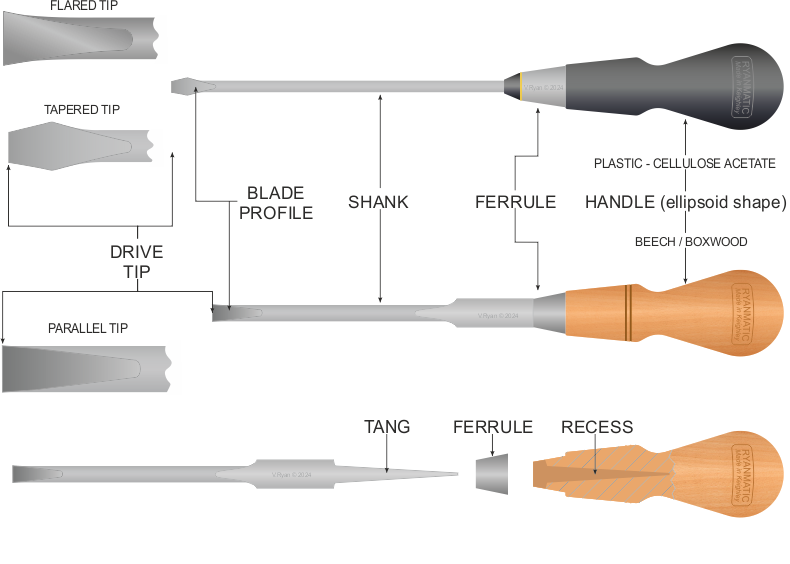

| THE CABINET SCREWDRIVER |

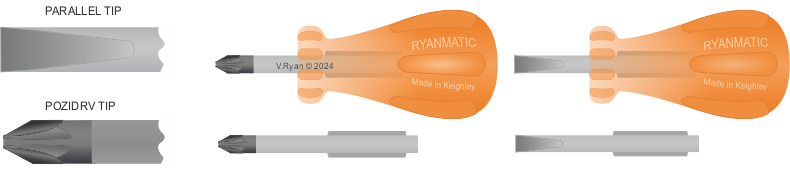

| Cabinet screwdrivers have either a tapered, flared or parallel blade profile. They have been designed, for use by cabinetmakers and allow access to tight spaces. They are perfect for turning screws in confined areas. The handle has an ellipsoid shape / form, making it comfortable in the hand, especially when applying pressure. |

|

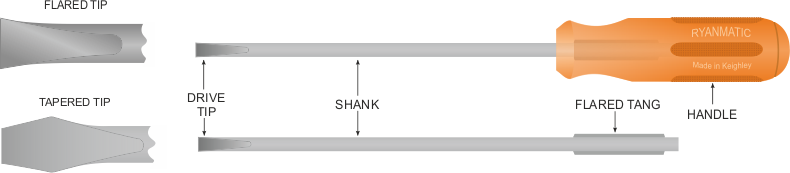

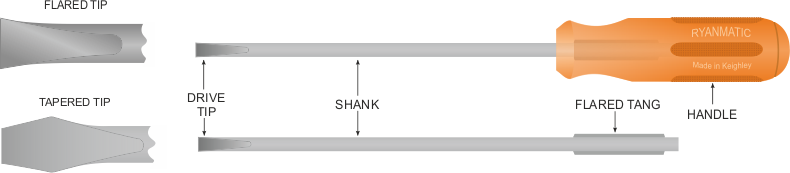

| THE ENGINEER’S SCREWDRIVER |

| Engineer’s screwdrivers were once regarded as specialized tools, used in the automotive industry. They tend to have a long thin shaft, capable of accessing difficult areas. Originally they were supplied with a parallel tip, although today they are supplied with a variety, including pozidrv and tapered tips. The engineer’s screwdriver has a slim handle with grips, that help finger tips to control the rotation of the screwdriver. The translucent plastic handle is manufactured from cellulose acetate butyrate. This is a durable and tough material. |

|

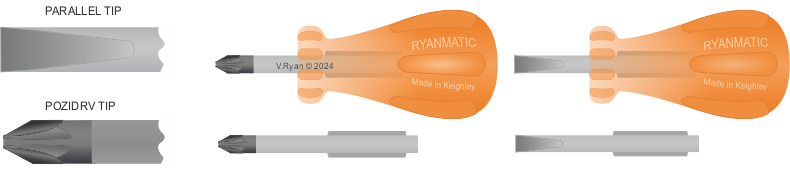

| THE STUBBY SCREWDRIVER |

| Stubby screwdrivers tend to have short blades, as they are designed to access spaces, inaccessible by other types of screwdriver. The handle tends to be rather ‘chubby’ and feels comfortable in the hand. The moulded finger grips of the handle, allow accurate / fine control of rotation. This type of screwdriver is found in screwdriver sets, because of their general usefulness. |

|

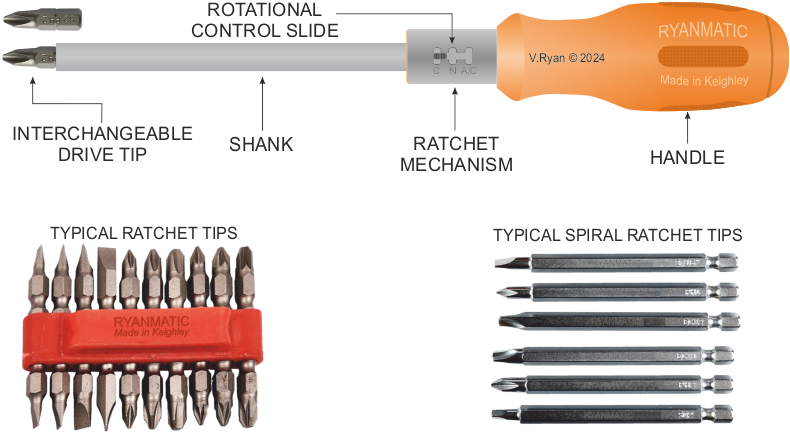

| RATCHET SCREWDRIVER |

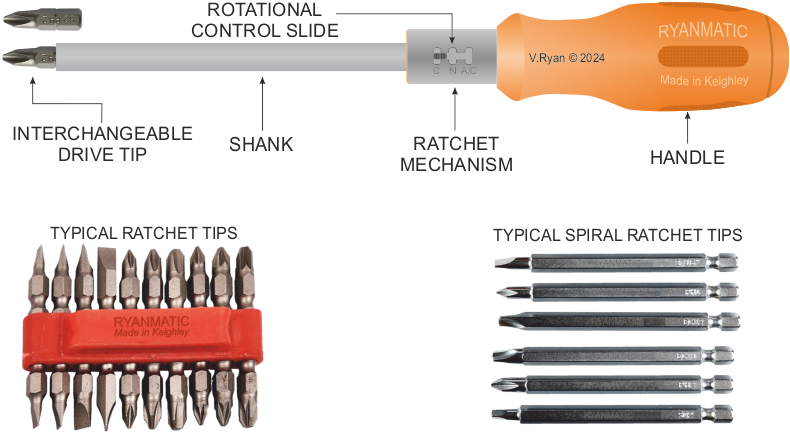

| After each turn of a normal screwdriver (such as a cabinet screwdriver), the tip of the screwdriver blade has to be repositioned, so that the following turn can be made. This can be inconvenient and wastes time. However, a ratchet screwdriver has an internal mechanism, that allows the screwdriver tip to stay in the slot of the screw. A quick reverse turn of the handle, and the user can apply force again. Most ratchet screwdrivers are supplied with a variety of interchangeable tips. The mechanism of the ratchet screwdriver, can be set for clockwise and anticlockwise movements. |

|

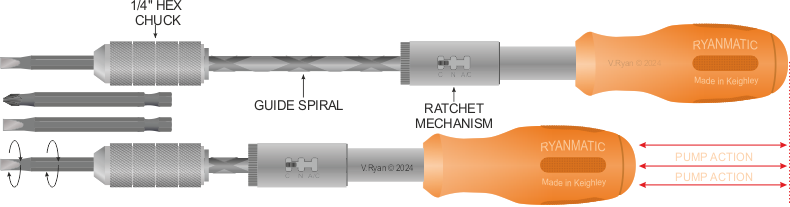

| PUMP ACTION - SPIRAL RATCHET SCREWDRIVER |

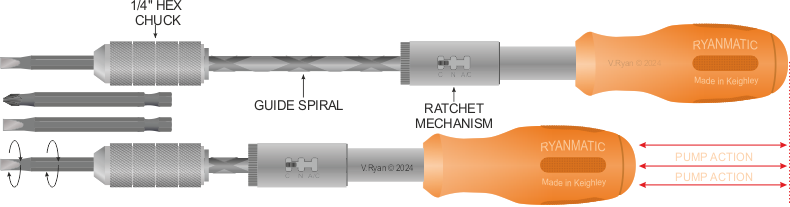

| This screwdriver also has a ratchet mechanism. Its overall length is much greater, due to the guide spiral. When using the screwdriver, the handle is pushed down and the guide spiral converts this pressure into rotary movement of the drive tip. A strong internal spring returns the handle to its original position. This is why it is sometimes called a pump action screwdriver |

|

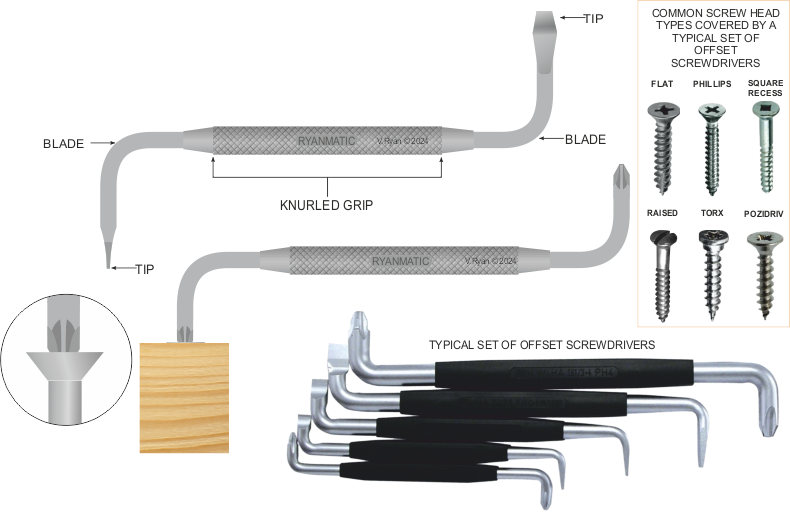

| OFFSET SCREWDRIVERS |

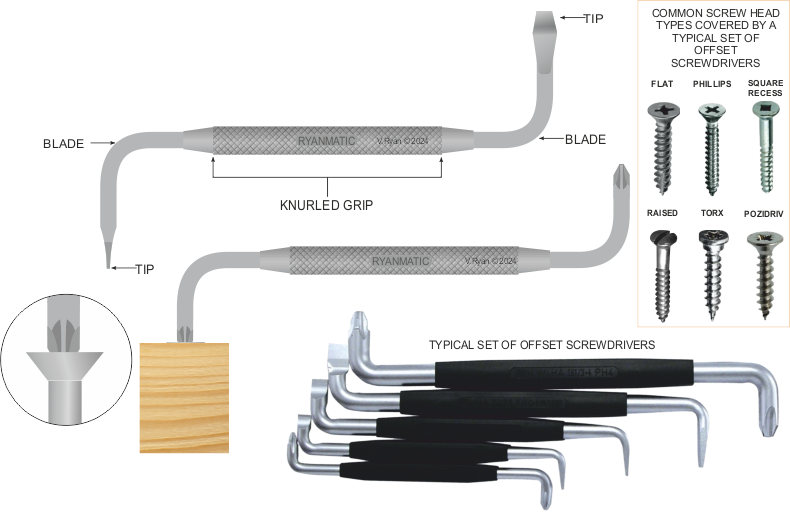

| Offset screwdrivers are useful when working in confined spaces, not suitable for a screwdriver with a handle. The offset design provides excellent torque, acting as a lever and increasing mechanical advantage. They are usually purchased as a set of five, each one having a different drive tip. The traditional offset, has a knurled central portion for grip. Some modern offset screwdrivers, have a comfortable ‘rubber’ grip. Offsets tend to be manufactured from high carbon steel, with hardened and tempered drive tips. |

|

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

|